Han Yan#, Xiaojun Dai#, Kunpeng Ruan, Sijie Zhang, Xuetao Shi, Yongqiang Guo, Huaqiang Cai* and Junwei Gu*. Flexible thermally conductive and electrically insulating silicone rubber composite films with BNNS@Al2O3 fillers. Advanced Composites and Hybrid Materials, 2021, 4: 36-50. (即时因子6.886)

(https://doi.org/10.1007/s42114-021-00208-1)

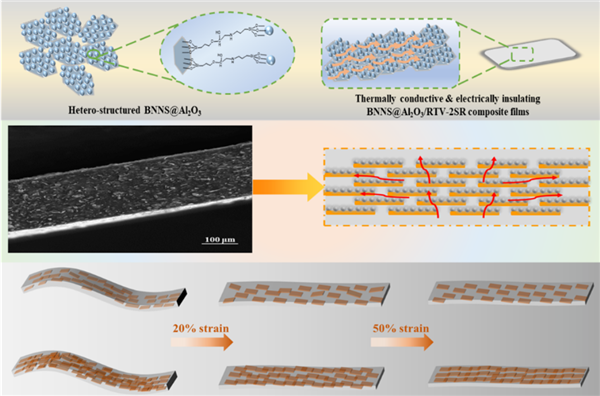

AbstractWith the advent of 5G era, the electronic and electrical industries are in increasingly urgent demand for flexible materials with high thermal conductivity coefficients (λ). In this paper, alumina (Al2O3) was chemically grafted to the surface of boron nitride nanosheets (BNNS) to prepare hetero-structured thermally conductive fillers (BNNS@Al2O3), and two-component room temperature vulcanized silicone rubber (RTV-2SR) was used as the polymer matrix. Then BNNS@Al2O3/RTV-2SR flexible thermally conductive and electrically insulating composite films were prepared by shear-coating. Results of X-ray photoelectron spectroscopy (XPS), Fourier transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA) and scanning electron microscope (SEM) showed that the BNNS@Al2O3 hetero-structured thermally conductive fillers with ‘point-plane’ structure were successfully prepared. The BNNS@Al2O3 hetero-structured thermally conductive fillers successfully achieved the synergy of Al2O3 and BNNS, and had more significant improvement on λ than single Al2O3, single BNNS and simply blending BNNS/Al2O3. When the amount of BNNS@Al2O3 was 30 wt% (BNNS/Al2O3, 1:1, wt:wt), the in-plane λ (λ∥) and through-plane λ (λ⊥) of the BNNS@Al2O3/RTV-2SR thermally conductive composite film reached 2.86 W/mK and 0.89 W/mK, 2.8 times λ∥ (1.01 W/mK) and 4.2 times λ⊥ (0.21 W/mK) pure RTV-2SR film, also higher than those of BNNS/RTV-2SR (with single BNNS, λ∥=2.46 W/mK, λ⊥=0.76 W/mK), Al2O3/RTV-2SR (with single Al2O3, λ∥=1.62 W/mK, λ⊥=0.49 W/mK) and (BNNS/Al2O3)/RTV-2SR (with simply blending BNNS/Al2O3, 1:1, wt:wt, λ∥=2.04 W/mK, λ⊥=0.62 W/mK) thermally conductive composite films with the same fillers amount. Meanwhile, the prepared BNNS@Al2O3/RTV-2SR thermally conductive composite film obtained excellent mechanical properties, electrical insulation properties and thermal properties. Its tensile strength, elongation at break, hardness, dielectric constant (ε), dielectric loss (tanδ), volume resistivity (ρv), glass transition temperature (Tg) and heat resistance index temperature (THRI) respectively reached 0.84 MPa, 175%, 27 HA, 3.89, 0.0088, 5.76×1011 Ω·cm, -40.1oC and 185.3oC. This work can provide a new idea for the preparation of hetero-structured thermally conductive fillers and flexible thermally conductive and electrically insulating composite films.

随着5G时代的到来,电子电气行业对于具有高导热系数(λ)的柔性导热材料的需求日益迫切。本文通过化学接枝法将氧化铝(Al2O3)接枝到氮化硼纳米片(BNNS)上,制备了一种具有“点-面”结构的二元异质结构导热填料(Al2O3@BNNS),然后以双组份室温硫化硅橡胶(RTV-2SR)为基体,通过剪切涂覆制备了Al2O3@BNNS/RTV-2SR柔性导热绝缘复合膜。结果表明,Al2O3@BNNS异质结构导热填料对RTV-2SR导热复合膜的导热性能具有协同提升效应。当Al2O3@BNNS用量为30 wt%(Al2O3:BNNS,1:1,wt:wt)时,Al2O3@BNNS/RTV-2SR导热复合膜的面内λ(λ∥)和面间λ(λ⊥)分别达到2.86 W/mK和0.89 W/mK,为纯RTV-2SR的λ∥(1.01 W/mK)和λ⊥(0.21 W/mK)的2.8倍和4.2倍,且优于相同填料用量下的BNNS/RTV-2SR(单一BNNS,λ∥=2.46 W/mK,λ⊥=0.76 W/mK)、Al2O3/RTV-2SR(单一Al2O3,λ∥=1.62 W/mK,λ⊥=0.49 W/mK)和Al2O3/BNNS/RTV-2SR(Al2O3/BNNS简单共混,1:1,wt:wt,λ∥=2.04 W/mK,λ⊥=0.62 W/mK)导热复合膜。并且,本文制备的Al2O3@BNNS/RTV-2SR导热复合膜兼具良好的力学性能、绝缘性能和耐热性能,当Al2O3@BNNS用量为30 wt%时,其拉伸强度、断裂伸长率、硬度、介电常数(e)、介电损耗(tand )、体积电阻率(ρv)、玻璃化转变温度(Tg)和耐热指数(THRI)分别达到0.84 MPa、175%、27 HA、3.89、0.0088、5.76×1010 Ω·cm、-44.1oC和185.3oC。本工作为异质结构导热填料及柔性导热绝缘复合膜的制备研究提供了一种新的思路,在5G电子电气设备领域具有潜在的应用。