Ping Song#, Bei Liu#, Chaobo Liang, Kunpeng Ruan, Hua Qiu, Zhonglei Ma, Yongqiang Guo and Junwei Gu*. Lightweight, flexible cellulose-derived carbon aerogel@reduced graphene oxide/PDMS composites with outstanding EMI shielding performances and excellent thermally conductivities. Nano-Micro Letters, 2021, 13: 91. 2019IF=12.264.(1区材料科学Top期刊)

(https://doi.org/10.1007/s40820-021-00624-4)

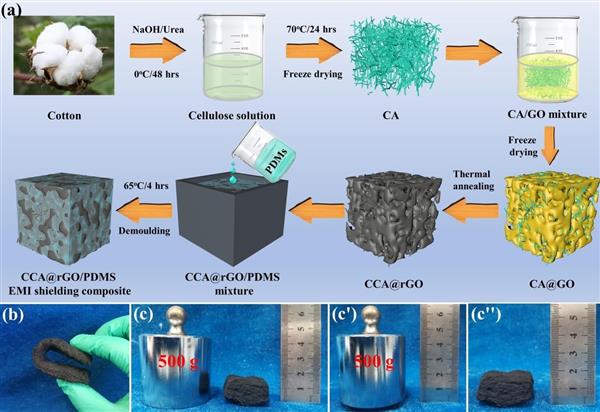

AbstractIn order to ensure the operational reliability and information security of sophisticated electronic components and to protect human health, efficient electromagnetic interference (EMI) shielding materials are required to attenuate electromagnetic wave energy. In this work, the cellulose solution is obtained by dissolving cotton through hydrogen bond driving self-assembly using sodium hydroxide (NaOH)/urea solution, and cellulose aerogels (CA) are prepared by gelation and freeze-drying. Then, the cellulose carbon aerogel@reduced graphene oxide aerogels (CCA@rGO) are prepared by vacuum impregnation, freeze-drying followed by thermal annealing, and finally the CCA@rGO/polydimethylsiloxane (PDMS) EMI shielding composites are prepared by backfilling with PDMS. Owing to skin-core structure of CCA@rGO, the complete three-dimensional (3D) double-layer conductive network can be successfully constructed. When the loading of CCA@rGO is 3.05 wt%, CCA@rGO/PDMS EMI shielding composites have an excellent EMI shielding effectiveness (EMI SE) of 51 dB, which is 3.9 times higher than that of the co-blended CCA/rGO/PDMS EMI shielding composites (13 dB) with the same loading of fillers. At this time, the CCA@rGO/PDMS EMI shielding composites have excellent thermal stability (THRI of 178.3oC) and good thermal conductivity coefficient (λ of 0.65 W/mK). Excellent comprehensive performance make CCA@rGO/PDMS EMI shielding composites great prospect for applications in lightweight, flexible EMI shielding composites.

为了保障精密电子元器件的运行可靠性及信息安全性、保护人体健康,需使用高效的电磁屏蔽材料来衰减电磁波能量。本文采用氢氧化钠/尿素溶液通过氢键驱动自组装溶解棉花得到纤维素溶液,经凝胶化和冷冻干燥制备了纤维素气凝胶(CA),进而采用真空浸渍-冷冻干燥-高温碳化制备了具有“皮-芯”结构的纤维素碳气凝胶@还原氧化石墨烯(CCA@rGO)气凝胶,最后浇注回填聚二甲基硅氧烷(PDMS)制备CCA@rGO/PDMS电磁屏蔽复合材料。得益于CCA@rGO的“皮-芯”结构特征成功构建了完善的三维双层导电网络,当CCA@rGO的用量仅为3.05 wt%时,CCA@rGO/PDMS电磁屏蔽复合材料在3 mm厚度下具有51 dB的优异电磁屏蔽效能(EMI SE)值,是相同填料用量的共混(CCA/rGO)/PDMS电磁屏蔽复合材料EMI SE的3.9倍(13 dB)。此时CCA@rGO/PDMS电磁屏蔽复合材料具有优异的热稳定性能(耐热指数THRI为178.3oC)和良好的导热性能(导热系数λ达到0.65 W/mK)。优异的电磁屏蔽性能和热稳定性能、以及良好的导热性能使CCA@rGO/PDMS电磁屏蔽复合材料在轻质、柔性电磁屏蔽复合材料和便携式、可穿戴电子设备等领域具有巨大的应用前景。