ChemistryWorld报道仿生研究工作进展

http://www.rsc.org/chemistryworld/2014/08/interview-yongmei-zheng-spider-silk-water-droplet

Yongmei Zheng:

Spider silk and butterfly wings

7 August 2014

by Jennifer Newton

Yongmei Zheng is a

professor of chemistry at Beihang University in

China. Research in the Zheng group looks at biological and bioinspired surfaces

with wettability functions.

Yongmei Zheng

Who or what inspired you to become a scientist?

Nature – there is

so much we can learn from it. Biological materials have a range of unimaginable

but smart functions. It is my aim to reveal these biological phenomena to

better the lives of human beings.

Can you give me a bit more detail on your overall

research aims?

I hope to

understand the natural laws of wettability on biological and bioinspired

material surfaces. We use physical, chemical and nanotechnology methods to

fabricate bioinspired functional surfaces with unique effects resulting from

gradients in micro- and nanostructures, to find wetting mechanisms such as

water repellency or water collection. We hope to develop these properties for

possible applications.

You’ve done a lot of work trying to recreate the

properties of spider silk – why is this such an interesting material?

Shiny water droplets on a spider''''s

web

After millions of

years, many creatures have evolved ways of making filamentous fibres. These

materials have been used in all sorts of applications including fabrics,

medical wound dressings and military applications. Silks have excellent

mechanical properties and chemical compositions. Spider silks are praised as

unique natural biomaterials with characteristics at both the chemical and

physical levels. They are undoubtedly the most excellent structural and

functional materials in nature.

We discovered that

the capture silk of the cribellate spider, Uloborus

walckenaerius, collects water from air.1 Its unique micro- and nanostructure, which is

characterised by periodic spindle-knots made of random nanofibrils that are

separated by joints made of aligned nanofibrils, gives rise to a combination of

gradients to achieve this cooperative effect that drives tiny water droplets

(under 100μm in diameter) toward the spindle-knots for highly efficient water

collection.

What is your research group working on at the moment?

Our group is

working to reveal the cooperative effect of multi-gradient micro- and nanostructured

(MN) interfaces on the surface of wettable materials – for example, how to use

chemical gradients, physical gradients, geometric gradients and responsive

wettability gradients, to control droplet behaviour.

We have found that

a multi-gradient MN cooperative effect can break through unsolved problems

regarding function on material surfaces, such as condensed droplet transport,

hysteresis limitations and water repellency at low temperatures.

We are pursuing

two main research routes regarding functional materials. One is characterising

water collection in materials like spider silk by looking at droplet transport,

droplet gathering and fogdrop harvesting from air. The other is characterising

water repellency on materials like butterfly wings by looking at

superhydrophobicity, anti-icing and ice-phobic effects.

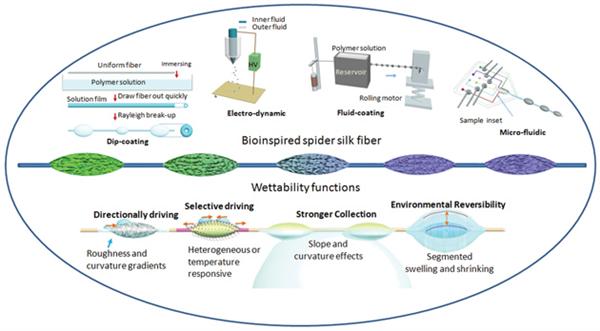

Inspired by the

role that micro- and nanostructures (MNs) play in the water collecting ability

of spider silk we have designed and made a series of fibres2 by integrating fabrication methods and

technologies, such as dip-coating, Rayleigh instability to break-up droplets

and phase separation, alongside strategies that combine electrospinning and

electrospraying, fluid-coating and wet-assembly.

Our structures can

be tailored to demonstrate the mechanism of multiple gradients in driving tiny

water droplets. Rough and smooth fibre surfaces, together with a chemical

gradient, can generate movement and control water droplets.

Ways to fabricate bioinspired fibres and

applications of bioinspired fibres with unique wettability

In the case of

larger water droplets, geometrically-engineered thin fibres have a much greater

water capturing ability than previously thought. This is due to the increased

stability of the phase contact line that combines ‘slope’ and ‘curvature’

effects on spindle-knots, providing sufficient capillary adhesion to retain the

hanging droplets. To extend this functionality, we have made bead-on-string

heterostructured fibres (BSHFs) out of poly-(methyl methacrylate) (PMMA) and

titanium tetrachloride (TiCl4) hydrolysed nanoparticles, via a one-step

electrohydrodynamic method that combines electrospinning and electrospraying

strategies. BSHFs can collect water by intelligently responding to

environmental changes in humidity. We are also developing a wet-assembly

technique that integrates electrospinning, particle fog and water condensation

to createheterostructured nanofibres.3

Can you explain where your work looking at butterfly

wings could be applied?

Butterfly wings

have multi-level oriented, anisotropic, or step-like micro- and nanostructures

on their surface to repel water in a particular direction.4 We have modelled the micro- and nanostructures of

butterfly wings to obtain a bioinspired surface. The excellent water repellency

of these bioinspired surfaces could have promising applications for controlling

droplets in micro-fluidics as self-cleaning, anti-adhesion, anti-icing and

anti-fogging surfaces.

What is the greatest challenge you face in your research

at the moment?

The greatest

challenge is developing ways to make robust and wettable materials on a large

enough scale to actually be applied.

REFERENCES

-

Y Zheng et al, Nature,

2010, 463, 640 (DOI: 10.1038/nature08729)

-

Y Chen and Y Zheng, Nanoscale,

2014, 6, 7703 (DOI: 10.1039/c4nr02064b)

-

L Zhao et al, Chem.

Commun., 2014, DOI: 10.1039/c4cc05156d

-

Liu et al, ACS

Nano, 2014, 8, 1321 (DOI: 10.1021/nn404761q); H Mei et al,Soft

Matter, 2011, 7, 10569 (DOI: 10.1039/c1sm06347b); Y Zheng et al, Soft Matter,

2007, 3, 178 (DOI: 10.1039/b612667g)