随着自动化和智能化的快速发展,光致软致动器在软体机器人等领域有着巨大的应用前景。液晶弹性体(LCE)兼具橡胶的弹性和液晶特性,可以在将其加热到向列型-各向同性相转变温度(Tin)以上发生时发生形变,在降温到向列型-各向同性相转变温度以下时恢复到原来的初始状态,因此是软致动器的理想材料。偶氮苯具有可逆的光响应性,含有偶氮苯基团的LCE已经被广泛应用于光致软致动器,然而偶氮苯LCE的设计和合成一般比较复杂。在LCE中添加具有较强光热转换能力的纳米填料是一种赋予LCE光致驱动功能的有效方法。纳米填料和LCE的光热转换能力以及与LCE的相容性直接影响了软致动器的机械性能和光致驱动性。开发光热转换能力强、与LCE相容性好的纳米填料成了制备LCE基光致软驱动器的关键之一。

华南师范大学张振课题组以聚多巴胺(PDA)包覆的MXene和纤维素纳米晶(CNC)和(PDA coated MXene and CNC, PMC)为LCE的光热和增强纳米填料,制备了一种具有可精确光调控、优异力学性能的LCE光致软驱动器。MXene具有优异的光热转换能力,被用作光热纳米填料;PDA具有优异的抗氧化性,用于增强MXene的抗氧化稳定性以及MXene与LCE间的相容性;CNC具有优异的分散性能和力学性能,用做分散剂以防止MXene在PDA改性时的团聚以及增强纳米填料。本研究制备的PMC-LCE光致软驱动器具有出色的光热转换能力和显著增强的机械性能(杨氏模量5.0 MPa,拉伸强度20.6 MPa, 断裂伸长率132.8%),能够举起其自身质量1500倍的重物,工作密度(89 kJ m-3)约是哺乳动物骨骼肌的两倍。通过近红外光调控、粘胶带、形状剪裁、液晶排列设计等,实现了一系列的光致驱动功能,比如爬、走、旋转以及游泳等。

该成果以Polydopamine coated MXene and cellulose nanocrystal as photothermal and reinforcing nanofiller for liquid crystal elastomer-based light-driven soft actuator为题发表在Journal of Colloid And Interface Science(影响因子9.4,中科院一区,JCR一区)上。该论文的第一作者为周口师范学院朱超胜和华南师范大学杨绍源,通讯作者为华南师范大学张振、南京工业大学褚良永和广西民族大学蓝平,共同作者为南开大学谢伟伟、广西名族大学蓝丽红、华南师范大学周国富、王蒙恩、曾怡舒等。

Figure 1. Schematic illustration of the fabrication of NIR-light driven LCE based soft actuator with PMC as photothermal and reinforcing nanofiller.

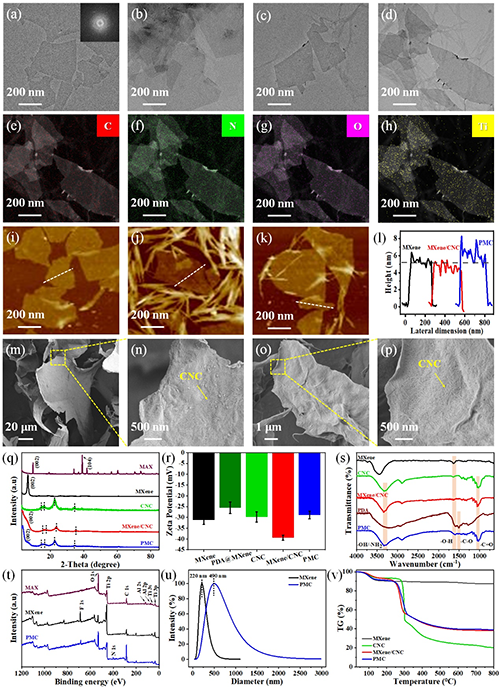

Figure 2. TEM image of (a) MXene, (b) PDA@MXene, (c) MXene/CNC, and (d) PMC. The (e) C, (f) N, (g) O, and (h) Ti elementary mappings of PMC. The AFM images of (i) MXene, (j) MXene/CNC and (k) PMC, and (l) their height morphology. The SEM images of freeze-dried (m & n) MXene/CNC and (o & p) PMC. (q) The XRD patterns of MAX, MXene, CNC, MXene/CNC, and PMC. (r) The zeta potential values of MXene, PDA@MXene, CNC, MXene/CNC, and PMC. (s) The FTIR spectra of MXene, CNC, MXene/CNC, PDA and PMC. (t) The XPS spectra of MAX, MXene, and PMC. (u) DLS results of MXene and PMC. (v) TGA curves of MXene, CNC, MXene/CNC, and PMC.

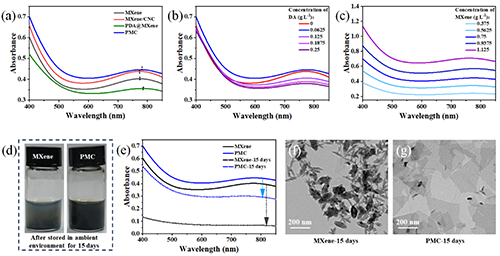

Figure 3. The UV-vis spectra of (a) MXene, MXene/CNC, PDA@MXene, and PMC aqueous dispersion. The UV-vis spectra of PMC dispersion with different concentrations of (b) DA and (c) MXene. The (d) digital images, (e) UV-vis spectra, and TEM images of (f) MXene and (g) PMC dispersion stored in ambient environment for 15 days.

Figure 4. Schematic preparation of PMC-LCE using a two-step thiol–acrylate method. (a) The molecular structures of RM257, EDDET, PETMP, and DMPA. (b) The preparation procedure of PMC-LCE and corresponding schematic states of PMC and LC molecules.

Figure 5. POM images of (a) pristine LCE and (d) its corresponding 45°-rotated LCE. The POM images of (b & c) PMC-LCE at different magnification and (e) its corresponding 45°-rotated PMC-LCE. (f) The XRD patterns of PMC-LCE before (polydomain) and after (monodomain) alignment. (g) DSC curves of pristine LCE and PMC-LCE. (h) The pristine LCE and PMC-LCE at 30℃ to 120℃. (i) The actuation strain of pristine LCE and PMC-LCE as a function of temperature.

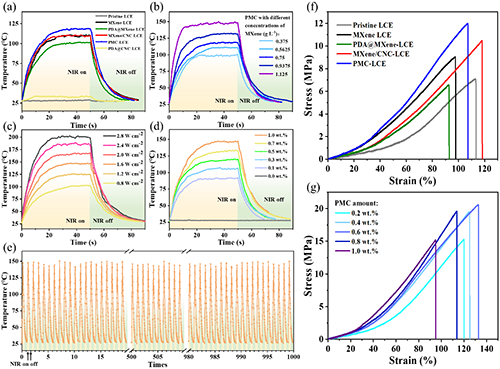

Figure 6. Photothermal conversion and mechanical performance of LCE films. Temperature of LCE under irradiation of 808 nm NIR laser with different (a) kinds of photothermal nanofillers, (b) concentrations of MXene in PMC, (c) NIR intensities, (d) amount of PMC, and (e) for 1000 NIR on-off cycles. Tensile stress-strain curves of LCE with (f) different kinds of nanofiller and (g) different amount of PMC as nanofiller.

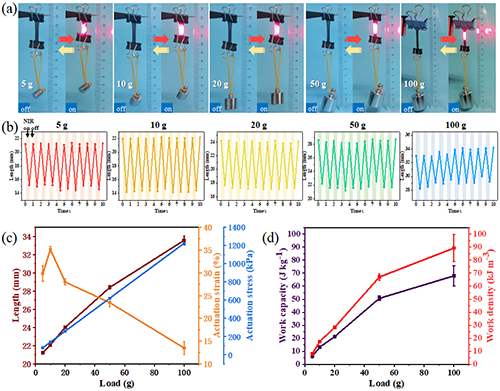

Figure 7. Loads lift testing of PMC-LCE driven by NIR laser at 808 nm at power intensity of 1.5 W. (a) Digital images of PMC-LCE films with NIR laser on or off with loads of different weights. (b) Lengths of PMC-LCE with 10 NIR laser on-off cycles with loads of different weights. (c) Initial lengths of PMC-LCE films before laser on and the actuation strains and stress as a function of loads of different weights. (d) Work capacities and work densities of PMC-LCE with loads of different weights.

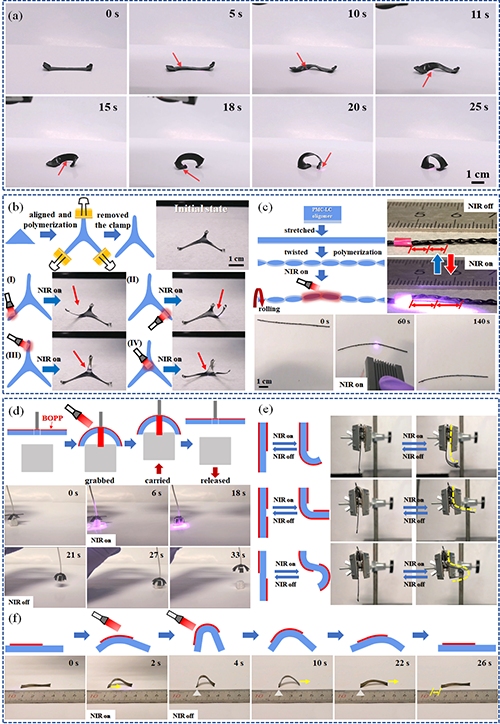

Figure 8. PMC-LCE applied as actuators (the red arrows represented the incident direction of NIR laser). (a) Actuator based on tuning NIR irradiation spot for flat-to-bridge shaped deformation. Actuators based on as-designed alignment with (b) tripod shape and (c) helix structure with rolling function. Actuators based on Janus structure functionalized as (d) soft clamp. (e) The J, L, S shaped actuators programmed from PMC-LCE film and (f) walking actuator.

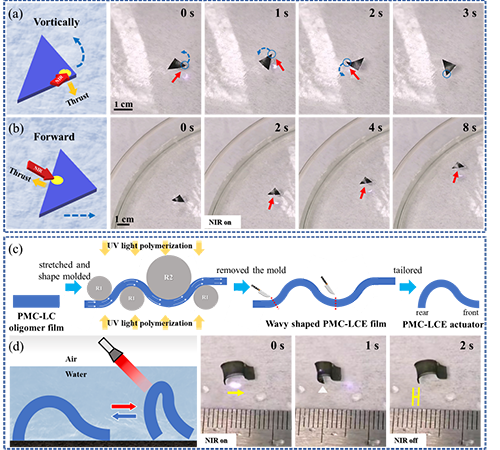

Figure 9. PMC-LCE aquatic actuators. PMC-LCE swimming actuator (a) rotated and (b) moved forward on the water surface with different NIR irradiation spots. (c) Schematic preparation of PMC-LCE underwater walking actuator. (d) The mechanism and images of PMC-LCE actuator walking underwater.

华南师范大学周国富教授团队张振课题组致力于纳米纤维素的绿色制备、表面性能调控、功能材料复合和应用等。通过纳米纤维素的绿色制备、表面改性、自组装和皮克林(Pickering)乳液组装等,构筑生物可降解、高性能、多功能的纳米纤维素基复合材料,并探索其广泛应用,致力于构建绿色环保、低碳、能源节约型社会。近年来,以一作或通讯作者在Advanced Functional Materials、Chemical Engineering Journal、Journal of Materials Chemistry A、Journal of Colloid And Interface Science、Small、Carbohydrate Polymers、ACS Applied Materials & Interfaces、ACS Sustainable Chemistry & Engineering等期刊发表论文40余篇,论文被引用3200次,H指数32;以第一发明人授权发明专利10项。

原文链接:https://doi.org/10.1016/j.jcis.2025.137834

- 西南大学曾建兵《Macromolecules》:聚多巴胺辅助构建高性能室温自修复导电弹性体 2025-10-19

- 新疆大学吐尔逊·阿不都热依木教授团队 CEJ: 聚多巴胺-PEDOT基便携式传感器用于氯丙嗪和诺氟沙星的同步测定 2025-09-05

- 新疆大学吐尔逊·阿不都热依木教授团队 AFM:利用3D Ti3C2Tx 混合电极材料增强电化学储能 2025-07-31

- 吉林大学徐雁教授/法国科学院 Yoshiharu Nishiyama教授《ACS Nano》:首次实现纤维素纳米晶右旋光子薄膜 2025-12-19

- 华南师大张振 Small:纤维素纳米晶稳定皮克林乳液法制备高潜热、热致变色的相变材料微胶囊及其在智能涂料上的应用 2025-07-09

- 波尔多大学Gilles Sèbe、华南师大张振 Carbohydrate Polymers:皮克林乳液界面SI-ATRP制备两亲性纤维素纳米晶 2025-05-19

- 北航王广胜/刘明杰/刘利民教授团队 Nat. Commun.:褶皱诱导格子结构MXene/PI薄膜应用于超薄电磁屏蔽领域 2026-01-18