随着智能纺织和可穿戴电子设备的迅猛发展,如何将高性能的能源存储单元柔性化、集成化,已成为纺织材料与能源科学交叉领域的前沿课题。传统的硬质液态电池难以满足织物在弯曲、折叠甚至拉伸状态下的性能需求。近日,浙江理工大学纺织科学与工程学院(国际丝绸学院)胡毅教授团队,从天然竹子的结构中汲取灵感,成功开发了一种仿生竹节结构复合固态电解质。这项创新性研究将纤维结构与电池电解质巧妙结合,为柔性可穿戴储能提供了全新的解决方案。该成果以《Biomimetic Bamboo-Node-Inspired Composite Electrolyte with Hierarchical Ion Pathways for Safe and High-Performance Solid-State Lithium Metal Batteries》为题,在国际权威期刊《Advanced Functional Materials》(影响因子19.0)上发表。论文第一作者为浙江理工大学纺织科学与工程学院(国际丝绸学院)博士研究生李德华,通讯作者为浙江理工大学博士生导师胡毅教授。

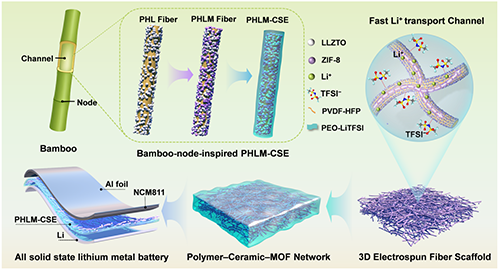

随着便携式电子设备和智能纺织品的快速发展,对兼具高安全性、高能量密度和长寿命的新型电池需求日益迫切。全固态锂金属电池(SSLMBs)因其固有的安全性和高能量密度潜力,被视为下一代电池技术的重要方向。然而,传统复合固态电解质(CSEs)因高聚合物结晶度、无机填料团聚以及不均匀的界面结构等固有缺陷,阻碍了其离子导电性的提升。为解决这些问题,浙江理工大学胡毅教授团队从天然竹子“中空通道引导、竹节强化”的分级结构中获得灵感,开发了一种仿生竹节结构复合固态电解质(PHLM-CSE)。在纺织领域,纤维和纱线是构建织物的基础,其结构直接决定了材料的性能。研究团队将这一理念迁移到电池电解质的设计中:利用静电纺丝这一纺织品制备的常用技术,将聚合物(PVDF-HFP)与无机填料(LLZTO)复合,纺制出三维多孔纳米纤维骨架。提供了优异的机械柔韧性和连续的离子传导路径。随后,通过原位自组装在纤维表面周期性地沉积ZIF-8颗粒,形成了类似“竹节”的微/纳米增强区域。这些“竹节”不仅显著提高了电解质膜的机械强度,还建立了高效的界面离子传输通道。

机理示意图:仿生竹节结构复合固态电解质(PHLM-CSE)及其分级离子传输通道的示意图。

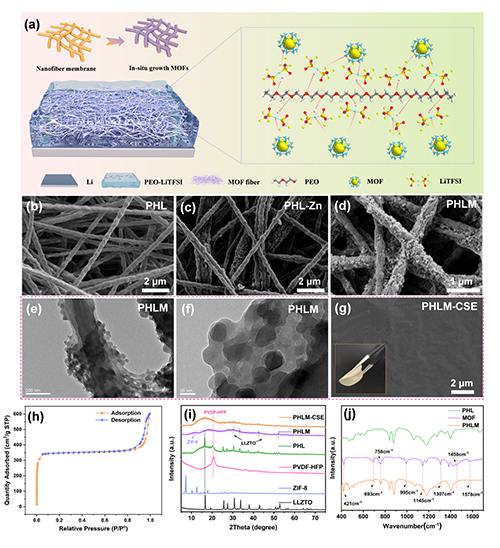

如图1所示,SEM结果显示:纯PVDF-HFP纤维表面光滑,而掺杂LLZTO后表面出现微纳级突起(图1b),证明无机颗粒成功嵌入纤维,构成稳定“主干”骨架。经原位自组装后,ZIF-8晶体均匀分布于纤维表面,无明显团聚(图1c–d),TEM进一步验证了其均匀沉积特征(图1e–f)。氮气吸附–脱附测试表明,ZIF-8具有高比表面积(1443.5 m2/g)和分级孔结构,有利于锂离子传输(图1h)。在PEO-LiTFSI浇筑后,所得PHLM-CSE膜表面致密、无裂纹(图1g),显著优于直接浇筑的PEO膜。XRD与FTIR结果(图1i–j)进一步确认了LLZTO的嵌入和ZIF-8的成功原位生长。

Figure 1. Structural design and morphological analysis of the PHLM-CSE composite solid-state electrolyte. (a) Schematic illustration of the three-dimensional architecture of the PHLM-CSE and the proposed mechanism by which MOF facilitates Li+ transport; (b) SEM image of the PVDF-HFP/LLZTO nanofiber membrane (PHL), scale bar : 2 μm; (c) SEM image of the PHL-Zn nanofiber membrane after Zn2+ ion adsorption, scale bar: 2 μm; (d) SEM image of the PHLM nanofiber membrane following in situ MOF growth, scale bar: 1 μm; (e, f) TEM images of the PHLM nanofiber membrane highlighting internal structure; (g) SEM image of the surface morphology of the PHLM-CSE electrolyte, scale bar: 2 μm. Inset: photograph image of the as-prepared membrane; (h) Nitrogen adsorption-desorption isotherm of the as-prepared ZIF-8 measured at 77.3 K; (i) XRD patterns of the PHLM-CSE electrolyte, PHLM and PHL membranes, pristine PVDF-HFP, ZIF-8, and LLZTO. Key diffraction peaks for PVDF-HFP, LLZTO, and ZIF-8 are indicated by dotted lines and arrows for clarity; (j) Fourier transform infrared (FTIR) spectra of the PHL, ZIF-8, and PHLM nanofiber membranes.

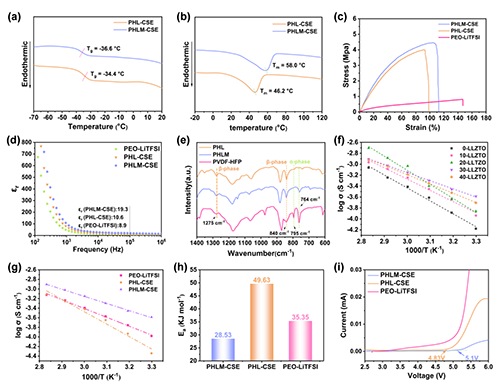

如图2所示,PHLM-CSE因MOF引入表现出更低的Tg(-36.6 °C)和更高的Tm(58.0 °C),兼具离子迁移性与热稳定性。其断裂强度和杨氏模量显著提升,具备更优抗枝晶能力。电学性能方面,PHLM-CSE展现出更高介电常数、更强盐解离能力,在50 ℃下电导率达5.04 × 10-4 S·cm-1,并具备5.1 V的宽电化学窗口,综合性能均优于对照组。

Figure 2. Structural features and electrochemical performance of the PHLM-CSE composite electrolyte membranes. (a) Differential scanning calorimetry (DSC) curves of PHL-CSE and PHLM-CSE electrolytes, highlighting their glass transition temperature (Tg) ; (b) DSC curves of PHL-CSE and PHLM-CSE in the higher-temperature region, illustrating thermal stability; (c) Stress-strain curves of PHL-CSE, PHLM-CSE, and PEO-LiTFSI electrolytes, revealing mechanical strength and flexibility; (d) Frequency-dependent dielectric constant (εr) of PEO-LiTFSI, PHL-CSE, and PHLM-CSE electrolytes; (e) FTIR spectra of PHL, PHLM and pristine PVDF-HFP membranes, demonstrating polymer phase characteristics and structural features; (f) Arrhenius plots of ionic conductivity (σ) versus temperature for PHLM-CSE electrolytes with varying LLZO contents; (g) Comparative ionic conductivity-temperature profiles of PEO-LiTFSI, PHL-CSE, and PHLM-CSE electrolytes; (h) Bar graph comparing the lithium-ion migration activation energy (Ea) across different electrolytes; (i) Linear sweep voltammetry (LSV) curves evaluating the electrochemical stability window of the investigated membranes.

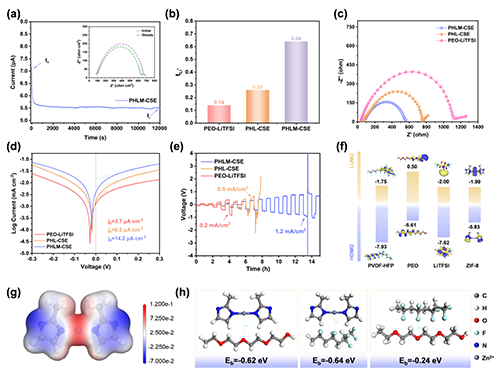

如图3所示,PHLM-CSE在50 °C下表现出快速稳定的恒压极化曲线,其锂离子迁移数高达0.64,远高于PHL-CSE(0.26)和PEO-LiTFSI(0.14)(图3a,b)。EIS结果显示其界面阻抗更低且长期稳定(图3c),交换电流密度达14.2 μA cm-2(图3d),并在0.8 mA cm-2下保持稳定电压平台(图3e),说明其具备优异的界面动力学和更高的临界电流密度,有效抑制锂枝晶生长。从电子结构上看,PVDF-HFP的低HOMO能级赋予体系良好抗氧化性,而ZIF-8与LiTFSI的低LUMO能级有助于优先形成稳定SEI(图3f)。其非均匀静电势分布(图3g)与较高结合能(图3h)进一步提升界面稳定性与Li+选择性迁移效率。

Figure 3. Electrochemical properties and interfacial stability analysis of the PHLM-CSE composite solid-state electrolyte. (a) Galvanostatic charge-discharge profiles of the PHLM-CSE-based cell, with the inset displaying the corresponding electrochemical impedance spectroscopy (EIS) data; (b) Comparison of lithium-ion transference numbers (tLi+) for PEO-LiTFSI, PHL-CSE, and PHLM-CSE electrolytes; (c) Electrochemical impedance spectra (EIS) of symmetric Li|PEO-LiTFSI|Li, Li|PHL-CSE|Li, and Li|PHLM-CSE|Li cells, reflecting interfacial resistance; (d) Linear sweep voltammetry (LSV) curves used to evaluate the electrochemical stability windows of different electrolytes; (e) Critical current density (CCD) measurements of Li|Li symmetric cells with PEO-LiTFSI, PHL-CSE, and PHLM-CSE electrolytes; (f) Molecular structures and corresponding HOMO-LUMO energy level diagrams of PVDF-HFP, PEO, LiTFSI, and ZIF-8; (g) Electrostatic potential distribution map of ZIF-8, indicating charge localization characteristics; (h) Binding energies (Eb) and optimized configurations of ZIF-8 interacting with PEO, PVDF-HFP, and their binary complex.

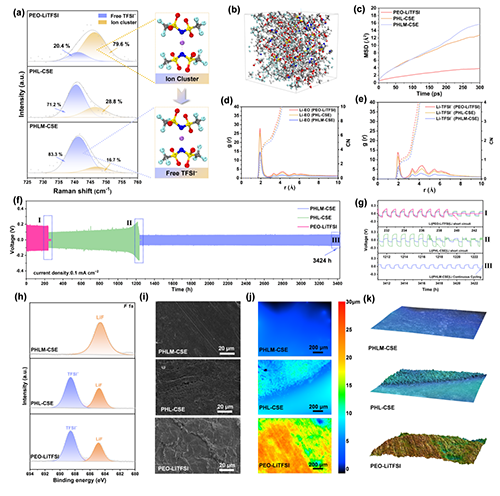

如图4所示,PHLM-CSE中TFSI-以解离态为主(83.3%),明显高于PHL-CSE(71.2%)和PEO-LiTFSI(20.4%)(图4a),表明MOF可削弱Li+–TFSI-作用、提升盐解离效率。MD模拟显示PHLM-CSE的Li+ MSD曲线斜率最高(图4c),RDF与CN结果(图4d,e)进一步证实其为Li+提供弱配位环境和有序扩散通道,从而显著增强迁移能力。在Li|Li对称电池中,PHLM-CSE循环稳定性超过2700圈(图4f),远优于PHL-CSE(1220圈)和PEO-LiTFSI(239圈)。XPS与EDS分析(图4h、S22)表明PHLM-CSE界面生成均匀的LiF主导SEI膜,抑制TFSI-分解并提升离子迁移效率。形貌表征(图4h–j)和原位显微观察(图4k)均显示其界面平整、无枝晶形成,进一步验证了其卓越的界面稳定性与抗枝晶能力。

Figure 4. Investigation of lithium-ion transport behavior and interfacial stability in PHLM-CSE composite solid-state electrolytes. (a) Raman spectra of PEO-LiTFSI, PHL-CSE, and PHLM-CSE composite electrolytes, highlighting variations in ion coordination environments; (b) Snapshot from a molecular dynamics (MD) simulation of the PHLM-CSE model system; (c) Mean squared displacement (MSD) curves of Li+ in PEO-LiTFSI, PHL-CSE, and PHLM-CSE electrolytes, reflecting ion mobility; (d) Radial distribution functions (RDFs) and coordination environments between Li+ and TFSI- in various electrolytes; (e) RDFs and coordination environments between Li+ and ether oxygen (–O–) atoms in the EO segments; (f) Galvanostatic cycling performance of Li|Li symmetric cells with PHLM-CSE, PHL-CSE, and PEO-LiTFSI electrolytes at 0.1 mA cm-2. (g) enlarged voltage profiles near the short-circuit or failure points in Li|PEO-LiTFSI|Li, Li|PHLM-CSE|Li, and Li|PHL-CSE|Li cell; (h) F 1s core-level XPS spectra of Li anodes after 100 cycles with different electrolytes; (i) SEM images of Li metal surfaces after cycling; (j) Two-dimensional laser confocal microscopy imagesshowing cycled surface morphology; (k) Three-dimensional laser confocal microscopy reconstructions of Li metal surfaces following long-term cycling.

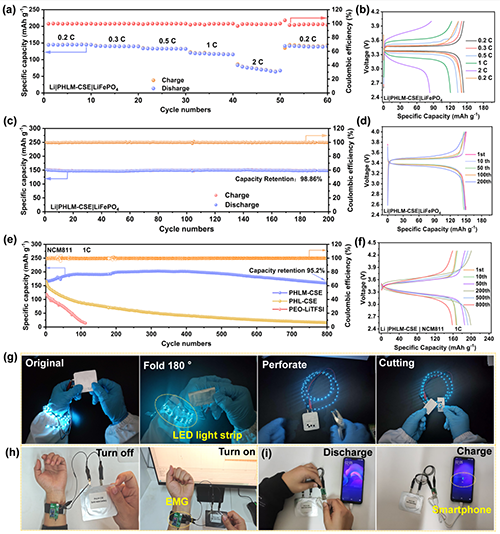

如图5所示,LiFePO?|PHLM-CSE|Li电池在0.2–2 C下保持高比容量(144.2→83.3 mAh g-1),倍率恢复良好(图5a,b),循环200圈后容量保持率达97.2%(图5c),在1 C下可稳定运行600圈以上。进一步在NCM811体系中,PHLM-CSE电池在1 C下循环800圈后仍保持95.2%容量(图5e,f),显著优于PHL-CSE和PEO体系,且表现出宽温适应性(20–60 °C)。这种优势源于MOF促进盐解离与Li+迁移,以及LLZTO增强界面稳定性和力学强度。在应用方面,基于PHLM-CSE的柔性软包电池在弯折、折叠、穿刺及火焰暴露下仍能稳定驱动LED(图5g),并在集成至肌电传感器与智能终端中表现出稳定供电(图5h,i)。其在0.2 C下容量约170 mAh g-1,库仑效率>99%,兼具高能量密度、安全性和柔性,展示了在可穿戴能源系统中的广阔应用前景。

Figure 5. Electrochemical performance and flexible applications of PHLM-CSE-based solid-state lithium metal batteries. (a) Rate capability and (b) corresponding charge–discharge profiles of LiFePO4|PHLM-CSE|Li full cells at various current densities. (c) Long-term cycling performance at 0.2 C and (d) corresponding voltage profiles. (e) Cycling stability of NCM811|PHLM-CSE|Li, NCM811|PHL-CSE|Li, and NCM811|PEO-LiTFSI|Li full cells at 1 C, and (f) their voltage profiles. (g) Optical images showing stable operation of a pouch cell under flat, folded, cut, and punctured conditions. (h,i) Demonstration of the pouch cell powering an electromyography (EMG) sensor and a smartphone, respectively.

总之,本研究受竹节结构启发,构建了仿生复合固态电解质(PHLM-CSE)。通过静电纺丝与原位ZIF-8组装形成连续离子通道和稳固网络,显著提升了离子传输与力学强度。PHLM-CSE在50 °C下具备高离子导电率(5.0 × 10-4 S·cm-1)、高迁移数(0.64)、宽电化学窗口(5.1 V)和优异力学性能。电池测试显示其兼具长寿命(对称电池>3400 h)、高稳定性(NCM811全电池800圈保持率95.2%)及柔性应用潜力,为实现高性能、本征稳定的固态锂金属电池提供了新思路。

在此,感谢浙江省自然科学基金项目(LY21E030023)和浙江理工大学嵊州创新研究院基金项目(SYY2024C000008)的支持!

通讯作者简介:胡毅,男,博士,教授,博士生导师。浙江理工大学纺织科学与工程学院(国际丝绸学院)副院长,主要从事非水介质染整新技术和柔性电子智能纺织品研究。以第一作者或通讯作者在Advanced Functional Materials, Energy Storage Materials,Advanced Fiber Materials, Nano Letters, Nano Energy等刊物上发表SCI论文70余篇,授权和转化国家发明专利30余项。获得国家级教学成果二等奖和浙江省教学成果特等奖各1项;主持获得中国纺织工业联合会教学成果一、二、三等奖,浙江省自然科学奖三等奖和中国商业联合会科技进步奖二等奖各1项。

原文链接:https://doi.org/10.1002/adfm.202514738

- 东华大学沈明武研究员/史向阳教授团队 AFM:仿生外泌体伪装的pH响应型树状大分子纳米凝胶作为疫苗通过重编程多种细胞类型治疗胰腺癌 2026-02-20

- 南京大学王炜/曹毅/薛斌团队 Nat. Commun.:仿生分级picot纤维水凝胶涂层实现超低摩擦与高耐磨性 2026-02-09

- 武汉大学刘兴海教授团队《Small》:仿生超韧快速响应水凝胶 2026-02-02

- 深圳大学田雷 AFM:用于高稳定性固态锂金属电池的离子导电分子接枝可持续纤维素基准固体复合电解质 2024-05-10

- 北化曹鹏飞教授受邀《Sci. China Chem.》Highlight:通过陶瓷/聚合物界面高效传输锂离子的复合电解质 2023-03-31

- 江南大学刘天西教授团队 Small:MOF基纤维网络增强聚合物复合电解质实现高性能全固态钠金属电池 2023-01-26

- 浙理工胡毅教授 Nano Energy:基于异质界面工程Janus结构复合纳米纤维膜实现高性能全固态锂金属电池 2025-05-20