随着智能纺织和可穿戴电子设备的快速发展,如何实现既柔性又安全的高性能能源存储成为科研前沿的重要课题。近日,浙江理工大学纺织科学与工程学院(国际丝绸学院)胡毅教授团队在国际著名期刊《Nano Energy》(影响因子16.8)在线发表了题为《Janus-structured composite nanofiber membranes with heterointerfacial engineering for high-performance all-solid-state lithium metal batteries》的研究论文。该研究提出了一种具有三维异构界面结构的Janus复合纳米纤维膜,显著提升了固态锂金属电池的离子传输效率和界面稳定性,为柔性智能纺织器件中的储能问题提供了创新性的解决方案。论文DOI:10.1016/j.nanoen.2025.111136。本文第一作者为浙江理工大学纺织科学与工程学院(国际丝绸学院)博士研究生李德华,通讯作者为浙江理工大学博士生导师胡毅教授。

在柔性电子设备和高安全储能系统迅速发展的背景下,固态锂电池因其优异的热稳定性与本征安全性,正逐渐成为下一代电池技术的核心方向。然而,单一无机固态电解质虽然导电性强,却脆弱且难以与柔性电子器件的软质界面相匹配;而纯聚合物电解质虽然柔软易加工,但离子导电性不足,难以满足高性能需求。复合固态电解质融合无机纳米颗粒的高导电性与聚合物的柔韧性,成为实现高效且安全储能的主流方案。传统研究多采用二维层状结构,但其异质界面面积有限,机械耦合效果不足,制约了材料在智能纺织等柔性领域的广泛应用。

为此,胡毅团队创新采用电纺技术,构筑了具有三维互穿Janus异质界面的复合纳米纤维膜。该结构在柔软的PVDF-HFP基底上定向固定LLZO纳米颗粒,并结合塑化剂优化聚合物结晶度,实现了离子传输路径的多元化和界面能量势的优化。该设计不仅显著提升了膜的机械强度(达到4.24 MPa),还实现了7.60×10-4 S·cm-1(50°C)高离子导电率和0.75的锂离子迁移数。理论计算显示,Janus膜表面的C-F官能团及路易斯酸碱活性位点有效促进锂盐解离,降低锂离子迁移能垒,形成稳定的Li3N/LiF界面SEI层,保证了锂金属的均匀沉积和长寿命循环。该复合电解质在实际柔性软包电池中展现出优异性能,能够驱动织物上的冷光发光装置(ACEL)和肌电传感器,在180度折叠、针刺、机械剪切及高温环境下依然稳定工作,完美契合智能纺织对柔性储能的需求。该研究不仅从材料结构设计层面突破了传统固态电解质在机械强度和离子传输之间的矛盾,更为智能纺织领域的能源集成提供了强有力的技术支撑。

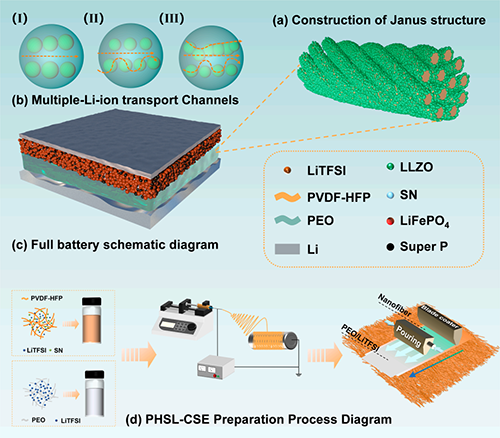

具体而言:该研究引入了一种Janus结构的复合纤维膜,通过在PEO基体内部创建异质界面,提供了多重离子传输路径。这种Janus结构的复合电解质(PHSL-CSE)是通过静电纺丝技术构建三维互穿网络实现的。这种Janus结构在PEO-LLZO界面构建了丰富的无机-聚合物异质界面,调控了离子传输行为,形成了多种锂离子传输通道:(i) PEO基体内的链段运动;(ii) LLZO颗粒形成的连续相;(iii) PEO-LLZO异质界面的空间电荷层。这些机制协同作用,显著提高了锂离子在电解质内的传输效率。

Fig. 1. Schematic illustration of the ion transport mechanism and fabrication process of the PHSL-CSE composite solid electrolyte with a three-dimensional interconnected Janus structure.(a) Representation of the Janus-structured composite fiber membrane, showcasing its unique heterogeneous interface and architecture.(b) Illustration of the multiple lithium-ion transport pathways enabled by the Janus structure, highlighting the role of the interconnected network in facilitating efficient ion migration. (c)Schematic of the full-cell configuration assembled with the PHSL-CSE composite solid-state electrolyte, demonstrating its integration into a practical solid-state lithium battery. (d) Step-by-step fabrication process of the PHSL-CSE composite electrolyte, emphasizing the formation of the Janus structure and the incorporation of functionalized components.

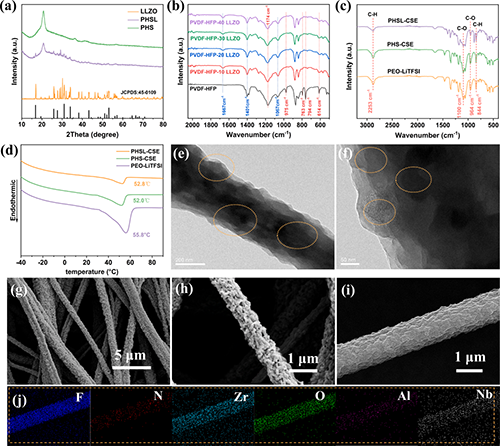

通过X射线衍射(XRD)、透射电子显微镜(TEM)、扫描电子显微镜(SEM)和元素映射等手段对材料进行了表征。结果证实了Janus结构的成功构建以及LLZO颗粒在纤维表面和内部的均匀分布。这确保了连续的离子通道和良好的界面相容性。傅里叶变换红外光谱(FTIR)分析表明,LLZO的加入降低了PVDF-HFP的结晶度,LLZO和SN协同促进了PVDF-HFP的脱氟化氢反应。差示扫描量热法(DSC)显示,Janus结构纳米纤维的引入显著抑制了PEO链段的结晶。热重分析(TGA)和高温测试表明,PHSL-CSE电解质具有优异的热稳定性和尺寸稳定性。机械性能测试显示,该电解质具有高机械强度(4.24 MPa)和良好的柔韧性。

Fig. 2. Comprehensive characterization of the Janus fiber membrane and electrolytes across different systems. (a) X-ray diffraction (XRD) patterns of LLZO, PHS-CSE, and PHSL (Janus) composite fiber membranes. (b) Attenuated total reflection Fourier-transform infrared (ATR-FTIR) spectra of PHSL fibers with varying LLZO content. (c) ATR-FTIR spectra of PEO-LiTFSI, PHS-CSE, and PHSL-CSE solid electrolyte films. (d) Differential scanning calorimetry (DSC) curves of PEO-LiTFSI, PHS-CSE, and PHSL-CSE solid electrolytes. (e, f) Transmission electron microscopy (TEM) images of PHSL (Janus) composite nanofibers at different magnifications. (g, h) SEM images of PHSL (Janus) composite nanofibers at varying magnifications. (i) SEM image of a single Janus fiber (j) Corresponding elemental mapping of the Janus fiber, illustrating the spatial distribution of key elements and confirming the structural heterogeneity of the Janus architecture.

Fig. 3. Mechanical and thermal properties of composite solid electrolytes and their molecular coordination mechanisms. (a) TGA curves of PHS-CSE and PHSL-CSE composite solid electrolytes. (b) Stress-strain curves of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes. (c) Raman spectra of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes within the 730–755cm-1 range. (d–f) Schematic molecular coordination models of (d) PEO-LiTFSI, (e) PH-CSE, and (f) PHS-CSE electrolytes. (g) Mean square displacement (MSD) profiles of lithium ions in PEO-LiTFSI, PH-CSE, and PHS-CSE electrolytes. (h) Radial distribution functions (RDF) and coordination numbers (CN) for Li+and TFSI-1 in PEO-LiTFSI, PH-CSE, and PHS-CSE electrolytes. (i) RDF and CN for Li+ and thylene oxide (EO) segments in PEO-LiTFSI, PH-CSE, and PHS-CSE electrolytes. (j) Digital photographs of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes before and after heating at 150°C for 30minutes. (k) Digital images showcasing the mechanical robustness of PHSL-CSE solid electrolyte films in various states, including original, curled, compressed, recovered, and in a suspended state under a 500g weight.

电化学性能方面,PHSL-CSE电解质在50°C时离子电导率达到7.60 × 10-4 S cm-1,锂离子迁移数为0.75。Arrhenius图显示其活化能较低。拉曼光谱和密度泛函理论(DFT)计算表明,PVDF-HFP对TFSI-阴离子有较强吸附作用,促进锂盐解离并抑制阴离子迁移。分子动力学(MD)模拟也支持了锂离子在复合电解质中更快的扩散。线性扫描伏安法(LSV)显示电化学窗口宽达4.94 V。

Fig. 4.Electrochemical performance of composite solid electrolytes. (a) Electrochemical impedance spectroscopy (EIS) spectra of the PHSL-CSE composite solid electrolyte at various temperatures. (b) Arrhenius plots of ionic conductivity for PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes. (c) Chronoamperometric response of Li | PHSL-CSE | Li symmetric cell; inset: Nyquist impedance spectra recorded before and after polarization. (d) Linear sweep voltammetry (LSV) curves of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes. (e) Energy level diagrams illustrating the highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) for PVDF-HFP, PEO, LiTFSI, and succinonitrile (SN). (f) Binding energies of TFSI- with SN, PEO, and PVDF-HFP. (g) Critical current density (CCD) curves of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes. (h) Interfacial resistance of the Li | PHSL-CSE | Li symmetric cell before and after 100 charge-discharge cycles. (i) Tafel plots of PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes.

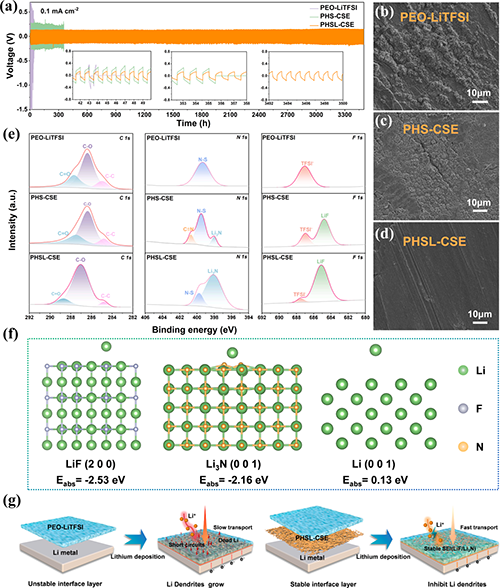

与锂金属负极的界面稳定性优异,Li/Li对称电池循环稳定性超过3500小时,这得益于Janus结构促进形成了富含Li3N/LiF的稳定SEI层。XPS分析和DFT计算证实了SEI的成分及其对均匀锂沉积和抑制枝晶生长的作用。XPS分析表明,循环后的Li | PHSL-CSE | Li电池在锂负极表面形成了富含Li3N/LiF的SEI层。DFT计算(吸附能)证实,Li+优先吸附在LiF和Li3N界面,抑制了锂枝晶的随机形核和生长。这种稳定的SEI层有效隔离了电解质与锂金属的直接接触,减少了副反应。

Fig. 5. Long-term cycling performance and morphological characterization of lithium metal surfaces.(a) Cycling stability of Li/Li symmetric cells with PEO-LiTFSI, PHS-CSE, and PHSL-CSE composite solid electrolytes at a current density of 0.1mAcm-2. (b-d) SEM images of lithium metal surfaces after 50 cycles for Li | PEO-LiTFSI | Li cells, and 100 cycles for Li | PHS-CSE | Li and Li | PHSL-CSE | Li cells. (e) XPS spectra of the lithium metal surfaces after cycling.(f) Adsorption energies of Li+ on LiF (200), Li3N (001), and Li (001) interfaces. (g) Schematic representation of the lithium deposition mechanism using PEO-LiTFSI and PHSL-CSE composite solid electrolytes.

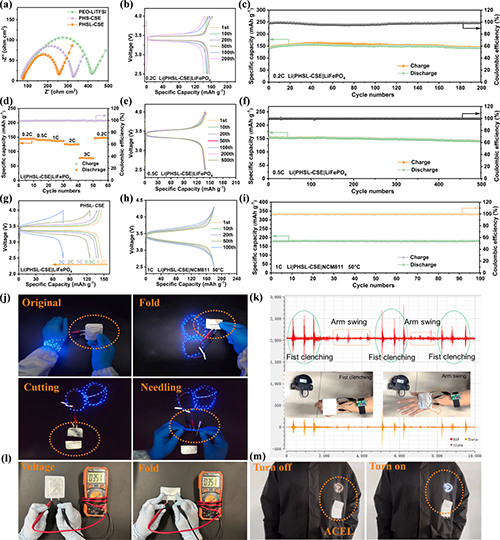

该电解质在全电池中也表现出色。LiFePO4 | PHSL-CSE | Li电池在0.5 C下循环500次后容量保持率仍很高。NCM811 | PHSL-CSE | Li电池在1 C下循环100次后也保持了良好的容量。更重要的是,采用PHSL-CSE电解质的柔性软包电池展现出卓越的集成能力和机械鲁棒性。即使在180°折叠、机械剪切、针刺和80°C热暴露等极端条件下,软包电池仍能稳定为ACEL发光器件和肌电传感器供电,显示出其在可穿戴电子设备领域的巨大潜力。

Fig. 6. Performance evaluation of all-solid-state lithium metal batteries at 50°C. (a) Electrochemical impedance spectroscopy (EIS) of Li | PEO-LiTFSI | LiFePO4, Li | PHS-CSE | LiFePO4, and Li | PHSL-CSE | LiFePO4 cells. (b) Voltage versus areal capacity curves for Li | PHSL-CSE | LiFePO4 cells. (c) Long-term cycling performance of Li | PHSL-CSE | LiFePO4 cells at a 0.2C rate. (d) Rate performance of Li | PHSL-CSE | LiFePO4 cells. (g) Voltage versus areal capacity curves at various rates for Li | PHSL-CSE | LiFePO4 cells. (e) Voltage versus areal capacity curves and (f) long-term cycling performance of Li | PHSL-CSE | LiFePO4 cells at a 0.5?C rate. (h) Voltage versus areal capacity curves and (i) long-term cycling performance of Li | PHSL-CSE | NCM811 cells at a 1C rate. (j) Optical images of Li | PHSL-CSE | LiFePO4 solid-state pouch lithium metal batteries, showing stable power output under various mechanical deformations including flat, bent, folded, cut, and punctured states.(k) A solid-state pouch cell integrated with an EMG armband, demonstrating the pouch battery''s capability to power a small vehicle via a flexible interface. (l) The pouch battery maintains stable output voltage even in a folded state. (m) Integration of the pouch battery with an ACEL flexible display, providing stable power to a flexible electronic device.

总而言之,这项研究通过Janus结构复合纳米纤维膜的异质界面工程,成功开发了一种高性能、柔性的全固态电解质。该电解质集高离子导电率、高迁移数、优异的机械/热稳定性和界面稳定性于一体,有效抑制了锂枝晶生长,并在柔性电池应用中展现出巨大潜力。这项工作为开发用于储能和可穿戴电子设备的高性能、柔性全固态锂电池提供了新思路。

在此,感谢浙江省自然科学基金项目(LY21E030023)和浙江理工大学嵊州创新研究院基金项目(SYY2024C000008)的支持!

通讯作者简介:胡毅,男,博士,教授,博士生导师。浙江理工大学纺织科学与工程学院(国际丝绸学院)副院长,主要从事非水介质染整新技术和柔性电子智能纺织品研究。以第一作者或通讯作者在 Advanced Functional Materials, Nano Letters, Energy Storage Materials, Nano Energy, Chemical Engineering Journal等刊物上发表SCI论文70余篇,授权和转化国家发明专利30余项。获得国家级教学成果二等奖和浙江省教学成果特等奖各1项;主持获得中国纺织工业联合会教学成果一、二、三等奖,浙江省自然科学奖三等奖和中国商业联合会科技进步奖二等奖各1项。

原文链接:https://doi.org/10.1016/j.nanoen.2025.111136

- 神奇的Janus颗粒让你轻松成为调酒师 - 首师大/清华梁福鑫团队连发Nature子刊:多级Janus结构热整流材料 2026-02-06

- 天津科大刘苇教授、侯庆喜教授团队 CEJ:高效多功能的Janus生物纳米复合膜用于可控的高灵敏水下制动器 2023-10-27

- 南开曹墨源/北航刘克松《Adv. Sci.》:兼具Janus结构和光热性能的智能除湿屋顶 2023-05-31

- 青科大李琼、浙大李志波 Adv. Mater.:利用缩氨硫脲动态键构筑动态共价-超分子协同网络 实现高性能可回收热固性树脂 2026-02-13

- 四川大学朱剑波教授团队 Nat. Mater.:高性能可循环聚合物发散性合成 2026-02-13

- 天津大学潘莉团队《Macromolecules》:中等立构/区域选择性催化剂设计高性能聚丙烯基弹性体 - 助力iPP增韧与HDPE/iPP共混物高效增容 2026-02-10

- 浙理工胡毅教授 Adv. Funct. Mater.:仿生竹节结构复合电解质为全固态锂金属电池提供新路径 2025-09-03