PVC是第二大合成材料,广泛用于建筑材料、包装材料、儿童玩具、家居用品、电线电缆,甚至用于血袋和尿袋、输血管等许多医疗用材料等,几乎涵盖了我们生活的方方面面。由于PVC分子的强极性,分子间有很大的作用力,需要借助增塑剂才可以进行塑化加工。与其他聚合物材料不同,在PVC材料中增塑剂是不可或缺的添加剂或配合物。经过近一个世纪的发展,已开发不同种类的近千种增塑剂,不仅可以满足不同塑化要求,而且决定最终制品的性能。甚至随增塑剂的加入量不同,PVC制品可以从硬质制品到软质制品随意调节。PVC增塑剂中,使用量最大是邻苯二甲酸酯类。其增塑效率高,适用范围宽,得到广泛应用。最具代表性的产品是邻苯二甲酸二异辛酯(DOP),占到整个增塑剂用量的60~70%。

但是,增塑剂有个致命缺陷。增塑剂是小分子,极易从PVC材料中迁移出来。随着增塑剂的流失,材料的性能也在逐步劣化而失去使用价值。所以,对增塑剂的要求中,除了溶剂化能力、相容性、高效率外,还要求保持性(Permanence)。为了阻止增塑剂迁移,开发出不少方法,如:制品表面交联、制品表面涂层等,但这些方法非常繁琐,只适用于一些特定应用。另外一个方法是聚合物增塑剂,增加增塑剂分子量,限制其迁移。然而,在限制增塑剂迁移的同时,也大大降低了增塑效率。

近20年来,增塑剂业面临另外一个重大挑战,增塑剂迁移而产生的污染问题引起重视,特别是增塑剂中用途最广的,效率最高的邻苯二甲酸酯类增塑剂因健康风险被多国限制使用。而替代产品的增塑效率远赶不上邻苯二甲酸酯类增塑剂。同时并没有解决迁移问题,只是用其他增塑剂替代邻苯二甲酸类增塑剂而已。这个问题看起来是邻苯二甲酸酯类本身的问题,其实还可以归结于增塑剂迁移问题。如果邻苯二甲酸酯不迁移出制品,就不会对人体和环境产生影响。欧盟等并没有限制迁移性较小分子量大的邻苯二甲酸酯就是例证。沿着这个开发思路学术界也有研究,虽然解决了迁移问题,但是邻苯二甲酸类增塑的高效率没有发挥出来。就目前状况而言,增塑剂开发似乎陷入一个怪圈,如果完全压制迁移,就要牺牲增塑效率,如果注重增塑效率,要以迁移为代价。如何平衡迁移性与增塑效率,开发无迁移并同时具有高效增塑性的PVC增塑剂是一个重要挑战。

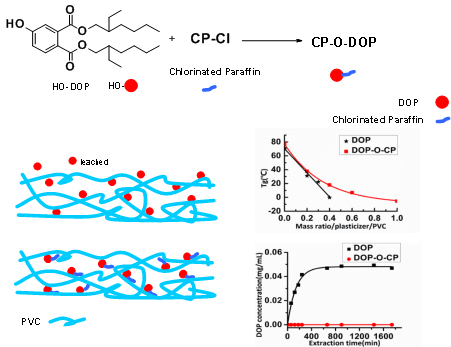

针对这一难题,北京化工大学程斌教授课题组提出新的解决思路——调节增塑剂与PVC之间的相互作用力,平衡增塑剂迁移性与增塑性。如下图所示,通过反应将DOP结构的分子与PVC相似结构的氯化石蜡结合成新的增塑剂。新的增塑剂增加了DOP与PVC的相互作用,限制了迁移,但是又不足以完全阻止增塑剂与PVC分子的“脱溶解”,所以仍能保持很高的增塑效率。

实验结果表明,新的增塑剂/PVC 0.3/1(wt/wt)以下,增塑效率与DOP相当,高于0.3/1时,增塑效率较DOP下降,但是增加新增塑剂的量,仍能将PVC的玻璃化温度降到0℃以下,能够满足绝大多数应用。溶剂抽提实验评价增塑剂迁移性表明,同等条件下,抽提4个小时后,DOP全部损失。新增塑剂抽提30小时,没有任何损失。显示出极强的抗迁移性。

研究结果发表在Nature出版集团旗下的Scientific Reports上。

论文信息及链接:

Jun Yuan & Bin Cheng. A Strategy for Nonmigrating Highly Plasticized PVC. Scientific Reports, 2017, 7, Article number: 9277 (2017). doi:10.1038/s41598-017-10159-7

https://www.nature.com/articles/s41598-017-10159-7

参考文献:

(1) Braun, D. Recycling of PVC. Prog. Polym. Sci.27(10), 2171-2195(2002).

(2) Rahman, M.,Brazel, C. S. The plasticizer market: an assessment of traditional plasticizers and research trends to meet new challenges. Prog. Polym. Sci. 29(12), 1223-1248(2004).

(3) Gayathri, N. S., Dhanya, C. R., Indu, A. R., Kurup, P. A. Changes in some hormones by low doses of di (2-ethyl hexyl) phthalate (DEHP), a commonly used plasticizer in PVC blood storage bags & medical tubing. Indian Journal of Medical Research. 119(4), 139-144(2004).

(4) Lee, K. Y. et al. Diverse developmental toxicity of di-n-butyl phthalate in both sexes of rat offspring after maternal exposure during the period from late gestation through lactation. Toxicology. 203(1), 221-238(2004).

(5) Thomas, J. A., Thomas, M. J., Gangolli, S. D. Biological effects of di-(2-ethylhexyl) phthalate and other phthalic acid esters. CRC critical reviews in toxicology.13(4), 283-317(1984).

(6) Janjua, N. R., Mortensen, G. K., Andersson, A. M., Kongshoj, B., Skakkebaek, N.E., Wulf, H. C. Systemic uptake of diethyl phthalate, dibutyl phthalate, and butyl paraben following whole-body topical application and reproductive and thyroid hormone levels in humans. Environmental science & technology. 41(15), 5564-5570(2007).

(7) Heudorf, U., Mersch-Sundermann, V., Angerer, J. Phthalates: toxicology and exposure. International journal of hygiene and environmental health. 210(5), 623-634(2007).

(8) Nagao, T. et al. Effect of butyl benzyl phthalate in Sprague-Dawley rats after gavage administration: a two-generation reproductive study. Reproductive Toxicology. 14(6), 513-532(2000).

(9) Lamb, J. C., Chapin, R. E., Teague, J., Lawton, A. D., Reel, J. R. Reproductive effects of four phthalic acid esters in the mouse. Toxicology and applied pharmacology. 88(2), 255-269(1987).

(10) Meeker, J. D, Sathyanarayana, S., Swan, S. H. Phthalates and other additives in plastics: human exposure and associated health outcomes. Philosophical Transactions of the Royal Society B: Biological Sciences., 364(1526), 2097-2113(2009).

(11) Rusyn, I, Corton, J. C. Mechanistic considerations for human relevance of cancer hazard of di (2-ethylhexyl) phthalate. Mutation Research/Reviews in Mutation Research. 750(2), 141-158(2012).

(12) Gupta, R. K. et al. Di-(2-ethylhexyl) phthalate and mono-(2-ethylhexyl) phthalate inhibit growth and reduce estradiol levels of antral follicles in vitro. Toxicology and applied pharmacology. 242(2), 224-230(2010).

(13) Reinsberg, J. et al. Effect of mono-(2-ethylhexyl) phthalate on steroid production of human granulosa cells. Toxicology and applied pharmacology. 239(1), 116-123(2009).

(14) Kluwe, W. M. et al. The carcinogenicity of dietary di (2‐ethylhexyl) phthalate (DEHP) in Fischer 344 rats and B6C3F1 mice. Journal of Toxicology and Environmental Health, Part A Current Issues. 10(4-5), 797-815(1982).

(15) Melnick, R. L. Is peroxisome proliferation an obligatory precursor step in the carcinogenicity of di (2-ethylhexyl) phthalate (DEHP). Environmental Health Perspectives. 109(5), 437(2001).

(16) Chipman, J. K., Mally, A., Edwards, G. O. Disruption of gap junctions in toxicity and carcinogenicity. Toxicological Sciences. 71(2), 146-153(2003).

(17) Choi, J., Kwak, S. Y. Hyperbranched poly (ε-caprolactone) as a nonmigrating alternative plasticizer for phthalates in flexible PVC. Environmental science & technology. 41(10), 3763-3768(2007).

(18)Adelia Ferreira Faria-Machado, Mariana Altenhofen da Silva, Melissa Gurgel Adeodato Vieira, Marisa Masumi Beppu. Epoxidation of Modified Natural Plasticizer Obtained from Rice Fatty Acids and Application on Polyvinylchloride Films. J. Appl. Polym. Sci. 127(5), 3543-3549(2013).

(19) Chen, J., Li, X., Wang,Y., Huang, J., Li, K., Nie, X. and Jiang1, J. Synthesis and application of environmental soybean oil-based epoxidized glycidyl ester plasticizer for poly(vinyl chloride). Eur. J. Lipid Sci. Technol. 119(5), DOI: 10.1002/ejlt.201600216(2017).

(20) Melissa Gurgel Adeodato Vieira, Mariana Altenhofen da SilvaI, André Costa Gomes Ma?umotoI, Lucielen Oliveira dos Santos, Marisa Masumi Beppu. Synthesis and application of natural polymeric plasticizer obtained through polyesterification of rice fatty acid. Materials Research. 17(2), 386-391(2014).

(21) Chiellini, F., Ferri, M., Morelli, A., Dipaola, L., Latini, G. Perspectives on alternatives to phthalate plasticized poly (vinyl chloride) in medical devices applications. Prog. Polym. Sci.38(7), 1067-1088(2013).

(22) Fernandez, S., Kunchandy, S., Ghosh, S. Linseed oilplasticizer based natural rubber/expandable graphite vulcanizates: Synthesis and characterizations. J. Polym. Environ. 23, 1–8(2015).

(23) Chavan, P., Gogate, R. Ultrasound assisted synthesis ofepoxidized sun?ower oil and application as plasticizer. J. Ind.Eng. Chem. 21, 842–850(2014).

(24) Choi, W., Chung, J. W., Kwak, S.Y. Unentangled Star-Shape Poly(ε-caprolactone)s as Phthalate-Free PVC Plasticizers Designed for Non-Toxicity and Improved Migration Resistance. ACS Appl. Mater. Interfaces. 6 (14), 11118–11128(2014).

(25) Erythropel, H.C., Shipley, S., B?rmann, A., Nicell, J.A., Maric, M. and Leask, R.L. Designing green plasticizers: Influence of molecule geometry and alkyl chain length on the plasticizing effectiveness of diester plasticizers in PVC blends. Polymer. 89, 18-27(2016).

(26) Erythropel, H.C., Dodd, P., Leask, R.L., Maric, M. and Cooper, D.G. Designing green plasticizers: influence of alkyl chain length on biodegradation and plasticization properties of succinate based plasticizers. Chemosphere. 91(3), 358-365 (2013).

(27) Kastner, J., Cooper, D.G., Mari?, M., Dodd, P. and Yargeau, V. Aqueous leaching of di-2-ethylhexyl phthalate and “green” plasticizers from poly (vinyl chloride). Science of the Total Environment. 432, 357-364(2012).

(28) Mercedes Cerezuela Barreto, Jochen Borris, Michael Thomas,Renate H?nsel, Michael Stoll, Claus-Peter Klages. Reduction of Plasticizer Leaching from PVC by Barrier Coatings Deposited Using DBD Processes at Atmospheric Pressure. Plasma Process. Polym. 9, 1208–1214(2012).

(29) Levin, G. Stabilized PVC products and their production. U.S. Patent 5,209,931, May 11, 1993.

(30) Levin G. Prevention of plasticizer migration from PVC products. U.S. Patent 4,806,393, Feb. 21, 1989.

(31 ) Messori, M. et al. Prevention of plasticizer leaching from PVC medical devices by using organic–inorganic hybrid coatings. Polymer. 45(3), 805-813(2004).

(32) Braslau R., Schaffner F., Earla A. Polymeric Phthalates: Potential Nonmigratory Macromolecular Plasticizers. Journal of Polymer Science. Polymer Chemistry. 51, 1175–1184(2013).

(33) Gooch, J.W. Polymeric Plasticizer 564 (Springer New York , 2011).

(34) Tarvainen, M., Sutinen, R., Somppi, M., Paronen, P., Poso, A. Predicting Plasticization Efficiency from Three-Dimensional Molecular Structure of a Polymer Plasticizer. Pharmaceutical Research. 18(12), 1760–1766(2001).

(35) Navarro, R., Pérez, P. M., Gómez Tardajos, M. and Reineckeet, H. Phthalate plasticizers covalently bound to PVC: plasticization with suppressed migration. Macromolecules. 43(5), 2377-2381(2010).

(36) Daniels, P. H. A Brief Overview of Theories of PVC Plasticization and Methods Used to Evaluate PVC-Plasticizer Interaction. J. Vinyl Addit. Technol. 15, 219–223(2009).

(37) Edmumd, H., Immergut and Herman F. MARK. Principles of Plasticization Plasticization and Plasticizer Processes., 1-26(1965).

- 青海大学刘秉鑫、高莉课题组 CEJ:通过加入环保型MgLaCe水滑石(LDH)揭示PVC薄膜的综合性能和安全性进步 2024-09-04

- 南工大材料学院 JCLP:基于一锅法“升级改造”(upcycle)策略制备双连续相导热功能材料 2023-12-15

- 北方民族大学郭生伟团队《J. Mater. Res. Technol.》:用于新型PVC建材的粉煤灰大宗高值利用 2023-02-26

- 南工大材料学院 IJBM :通过加入ADR扩链剂和生物资源增塑剂-增强聚(乳酸)和聚(对苯二甲酸-己二酸丁二醇酯)共混物的韧性 2025-01-03

- 北化冯岸超副教授和澳大利亚学者合作《Macromolecules》:在RAFT聚合制备星形聚氯乙烯增塑剂领域取得新进展 2021-06-03

- 天大陈宇教授&美国橡树岭国家实验室曹鹏飞研究员团队:一种赋予聚氯乙烯基塑料高度可伸缩性、超韧性以及多功能性的绿色大分子添加剂 2021-04-08